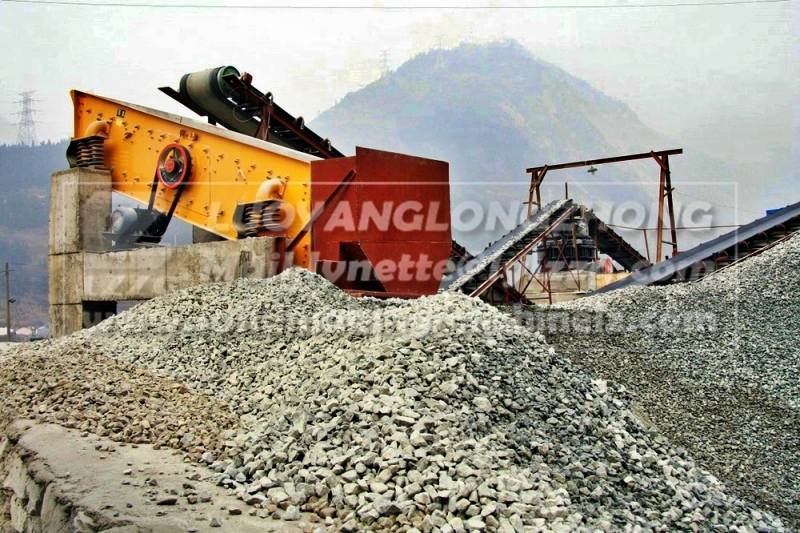

400tph diabase sand making plant process flow

Process flow and equipment for diabase crushing, sand making…

Tel: 86-379-65160016

Fax: 86-379-65160018

Email: export@lylzzg.com

In nature, copper ore generally contains a mixture of copper sulfide and copper oxide. Concentrators usually use flotation to improve the ore grade, so that pure copper can be smelted later. A variety of mining equipment is used in the process of flotation of copper ore. Listen to our introduction one by one.

1. Feeding – vibrating feeder

vibrating feeder

The vibrating feeder is widely used in metallurgy, coal mine, mineral processing, building materials and other industries. The material is pre-screened first.

2. Coarse crushing – jaw crusher

The jaw crusher is mainly used for coarse crushing in sand and gravel yard, metallurgy, mining, chemical industry and other industries. The compressive strength can reach 320MPa.

Large pieces of copper ore should be crushed into smaller pieces by jaw crusher first, so as to meet the feeding granularity of medium crushing.

3. Medium crushing – cone crusher

The cone crusher is mainly used for medium and fine crushing of ores with medium and above medium hardness, and can process 12-1000 tons of materials per hour.

The hardness of copper ore is relatively high, which is just suitable for crushing by cone crusher. After processing by cone crusher, finished products of 3-60mm size are produced.

4. Screening – circular vibrating screen

Circular vibrating screen

The function of the vibrating screen is to screen out the materials that meet the particle size of the next feeding, and at the same time collect the unqualified materials and re-send them to the crushing equipment to be crushed again until the particle size is qualified.

For example, the discharge particle size of the cone crusher is 3-60mm, and in the next grinding process, the feed particle size of the ball mill is required to be below 20-25mm, and the vibrating screen can be used to separate the materials of different particle sizes, and the materials below 20mm are fed into In the ball mill, more than 20mm is sent back to the cone crusher for re-crushing.

5. Grinding – ball mill

The function of the ball mill is to further grind the material into fine particles of 0-200 mesh in order to meet the conditions of the next flotation.

The feed particle size of the ball mill is 20-25mm or less, and the discharge particle size is 0.074-0.89mm. It can produce 0.65-615 tons of materials per hour. It is very popular in cement, silicate products, new building materials, refractory materials and other industries. .