The price of 300 tons/hour dewatering screen in South Africa

The dewatering screen is used in conjunction with the user's…

Tel: 86-18736301510

Fax: 86-379-65160018

Email: export@lylzzg.com

2019-09-04

Concentrated dry discharge and backfilling of tailings refers to the use of concentrated dewatered tailings produced during the beneficiation process to fill the voids produced by underground mining. Tailings backfilling can be said to be one of the most common methods of treating sludge and tailings that may contain hazardous materials, reducing surface environmental impact by storing tailings on the ground.

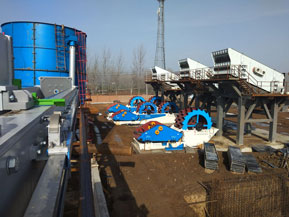

General flow chart

The tailings are concentrated and dehydrated by high-efficiency concentrators and vacuum disc filters, usually as part of the “sludge” of mine backfilling. The filter cake is first discharged into a weighing hopper and then added to the mixing hopper or continuous mixer in batches, during which some binder and other materials are added.

The bonded paste is then transported through subterranean high pressure wear a resistant slurry pump or distributed by gravity, depending on the particular location. Most backfill projects in the world use traditional flow charts with concentrators, tailings dewatering screens and vacuum disc filters. Because there is less water in the filter cake, less cement binder is required. This is a backfill operation. The main operating costs.

In underground mining, high-efficiency concentrators, tailings dewatering screens and filters are among the best choices for slurry backfill solutions. There are some shallow mines and backfill operations for long distance operation. The choice of the slurry pump is also very important. The wear resistant slurry pump is a good choice.