Mining Indonesia 2025

Exhibition Name: The 23rd International Mining & Mineral Rec…

Tel: 86-18736301510

Fax: 86-379-65160018

Email: export@lylzzg.com

2021-08-31

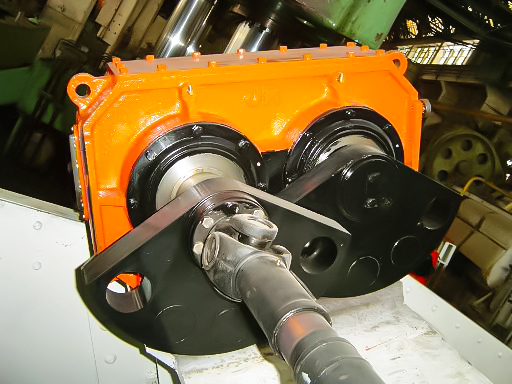

The banana screen is mainly composed of three main structures: vibration exciter/screen box/elastic support. The motor drives the vibration exciter shaft to rotate through the belt pulley angle belt and the intermediate shaft through the cross coupling. The shaft end has an eccentric block through the eccentric block. The vibration exciter is installed on the box-shaped girder of the screen box, and the screen box is installed on the base through the support of springs, etc., so that the banana screen can form continuous vibration to effectively control the coal. deal with. It has the advantages of large processing capacity, high screening efficiency, low energy consumption, simple transmission system, reliable operation, and convenient maintenance.

The basis of the vibration exciter bearing fault judgment is the bearing: temperature and noise. These two conditions can be more intuitively and conveniently monitored in production. However, due to differences in design, manufacturing, and assembly, the temperature and noise value of each exciter is not exactly the same. Therefore, it is necessary to register the original temperature and noise data of each vibration exciter, and to judge the use status of the bearing through regular monitoring and comparison.

The main sources of noise are gear meshing, bearing rolling, eccentric block rotating air friction and so on. The temperature mainly comes from the lubrication system, assembly conditions, machining accuracy, and friction between components. Under normal working conditions, the exciter rarely has a sudden increase in noise and temperature rise. But once this phenomenon occurs, and when it does not improve, the noise increases by more than 10dB, and when the temperature rises above 10℃, it must be shut down and checked: lubricating oil, seals, eccentric blocks, magnetic blockages, etc., and deal with problems in time to prevent sudden occurrences. Locked instantly, resulting in a more serious accident.

The bearing working condition of the banana screen vibrator is very bad. Compared with the bearing of general mechanical transmission, the load it bears is the impact load produced by the centrifugal force of the eccentric mass rotating at high speed, and this load is a kind of high frequency. Alternating load. At the same time, due to the effect of heat, the elongation of the shaft will also affect the service life of the bearing. At the same time, environmental dust and sealing conditions have a greater impact on the use of bearings. Therefore, the vibration exciter needs to be maintained regularly, mainly by adding lubricating oil regularly, and checking the operating conditions of the machine.