Mining Indonesia 2025

Exhibition Name: The 23rd International Mining & Mineral Rec…

Tel: 86-18736301510

Fax: 86-379-65160018

Email: export@lylzzg.com

2021-12-14

Failure to replace worn support beams in time

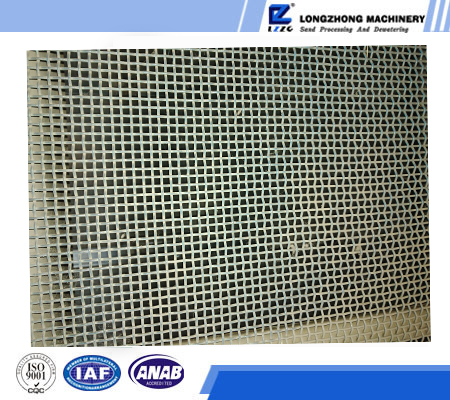

After the support beam of the vibrating screen is worn, sharpening, deflection and unevenness will appear, and the sharpened part is like a knife edge. Analysis believes that when the vibrating screen vibrates at high frequency, the sharpened, deviated, and uneven support beams will continuously impact, wear, and cut the ribs of the screen, causing the screen to rupture and perforate prematurely.

There is a problem with the amount of feed

In the production process, if there are phenomena such as uneven feeding, excessive feeding drop, and excessive feeding flow, it will cause the screen to rupture and perforate. If the screen feed is uneven, it may cause excessive force on the screen mesh; if the feed drop exceeds 300mm or the feed flow is too strong, its impact on the screen will be greater.

1. Improve the feeding conditions, reduce the feeding gap, reduce the feeding flow, and make the feeding uniform.

2. Improve the installation quality of the screen, so that the screen reinforcement and the supporting beam are completely consistent to ensure the supporting area of the screen.

3. Replace the worn support beams in time.

4. When there is no new support beam to be replaced, temporarily lay waste bicycle tires between the screen and the worn support beam, which can reduce and avoid the wear of the screen by the sharp corners of the support beam.