How to adjust the sand particle size of the roller sand making machine?

The hydraulic system of the roller sand making machine can b…

Tel: 86-379-65160016

Fax: 86-379-65160018

Email: export@lylzzg.com

2021-10-22

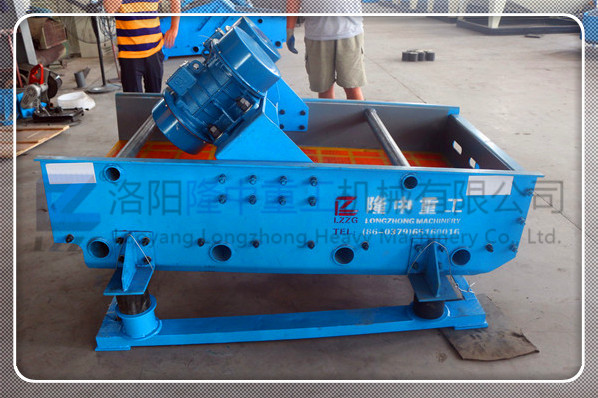

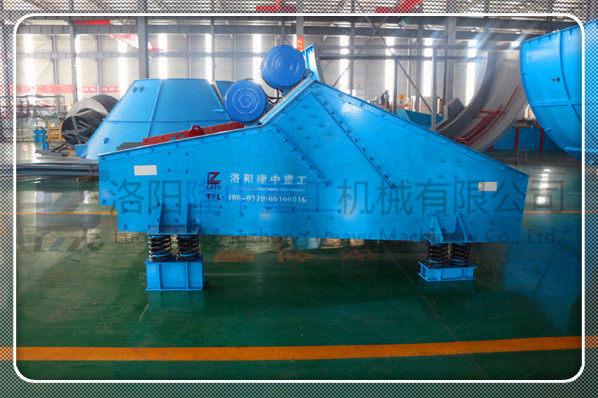

When the dewatering screen is used for a long time, rusting of the machine is a relatively common problem. Many dewatering screens are made of steel. It is easy to rust when used in the open air environment or raining for a long time. In addition, when the hardness of the rock, ore, etc. dehydrated by the dehydration screen is high, the friction during the dehydration process will be severe, and the vibration dehydration chamber will rust. If it is not handled in time, the performance of the equipment will be reduced.

Rusty components of the dewatering screen will increase maintenance costs, forcing manufacturers to replace equipment and construction. Therefore, for stone manufacturers, mastering some dewatering screens for rust and rust removal is essential to ensure production safety and efficiency.

In order to prevent premature rust and corrosion of the dewatering screen, it is important to enhance the maintenance of the dewatering screen. The manufacturer is good at arranging professionals to maintain the dewatering filter regularly. Fragments should be treated with conventional preservatives. Anti-oxidant coatings (such as mineral coatings and spray coatings) can also be used to prevent rust from coming into contact with water and air.

For the dewatering screen that cannot work for a long time, it is necessary to strengthen maintenance, check whether the paint is complete, and try to avoid direct connection between the bottom of the dewatering screen and the ground. It must be protected with appropriate grease.

Vibrating screen anti-rust method

1. Chemical descaling method: Use acid to remove the rust on the surface of the dewatering screen. This method can only be used in the production workshop, pay attention to safety and avoid direct contact with the human body.

2. high-pressure water mill rust removal: using the impact of high-pressure water jets to remove corrosion on the steel plate, this method will not produce dust pollution, and will not damage the steel plate, and the rust removal effect is better. However, this method is more prone to rebound problems.

3. electric descaling method: mainly use electric or compressed air, equipped with a suitable descaling device to achieve descaling effect, this method is more adaptable and can be applied to any.