How to adjust the sand particle size of the roller sand making machine?

The hydraulic system of the roller sand making machine can b…

Tel: 86-379-65160016

Fax: 86-379-65160018

Email: export@lylzzg.com

2021-11-30

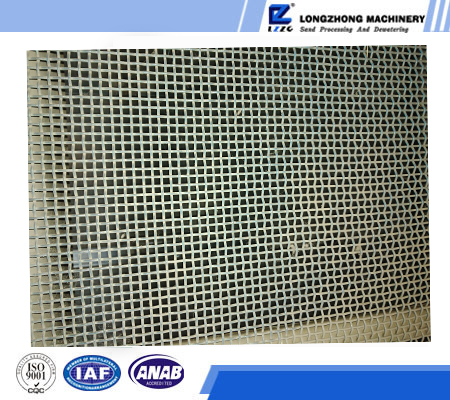

Manganese steel screen is a kind of metal mesh structure element used for sieving and filtering. It is widely used in screening, filtration, dewatering, desliming and other operations in many industries. It has high strength, rigidity and bearing capacity, and can be made into rigid screening and filtering devices of various shapes.

Product specifications: Flat screen, curved screen, polyurethane screen, woven raw coal screen, slotted screen. The manganese steel ore screen is a kind of screen product woven by manganese steel mesh wire with a diameter of 1.6mm-12mm. It adopts an embedded (Mn65-Q) weaving method, and the overlapping points of warp and weft are not prominent. Flat and uniform force. The hardness is HB180-230, which has good plasticity and toughness.

When subjected to strong impact and friction, the surface will produce strong work hardening due to plastic deformation, and the surface hardness can be increased to above HRC60, so as to obtain high wear resistance, while the interior still maintains high plasticity and toughness. When the old surface is worn out, the new surface will form a wear-resistant layer, so the service life can reach 4-8 times that of ordinary screens. Therefore, it is mostly used in large-scale coal mines. It can also be used for professional mechanical vibrating screens and drums. Screening machine, electromagnetic high-frequency screening machine, and asphalt mixing machine are used as protective nets.

Mine screen product use

Uses: Manganese steel screens can be used in mining, coal, petroleum, fertilizer, food, environmental protection and other industries.

The manganese steel mesh screen is a newly developed product developed in the mine screen family recently. It is characterized by easy leakage, wear resistance and corrosion resistance. The mesh section is trapezoidal. The gap is narrow at the top and wide at the bottom. Its main applications are: filter cartridges, polyurethane sieve plates, flat sieve plates, woven raw coal sieves, oil filters, salt industry meshes, centrifuge baskets, filters, and stainless steel mesh sets.

Selection of screen

When choosing a vibrating screen, you can choose a screen that can meet our screening needs according to the size of the material to be screened. Describe the technical parameters of the screen mesh, wire diameter, aperture, diameter, material, effective screen surface, etc. The length unit is usually millimeter (mm) as the standard.