How to adjust the sand particle size of the roller sand making machine?

The hydraulic system of the roller sand making machine can b…

Tel: 86-379-65160016

Fax: 86-379-65160018

Email: export@lylzzg.com

2021-09-28

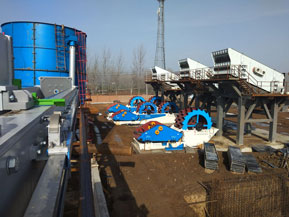

Qingdao Xiaojianxi Phase II Domestic Waste Incineration and Sludge Co-processing Project. The total investment of the project is about 1.42 billion yuan, and the total area is 137.2 mu. The project is mainly responsible for the waste treatment in the five districts of Shinan District, Shibei District, Licang District, Laoshan District and Chengyang District.

The whole plant process is mainly composed of the following systems: garbage weighing and unloading system, sludge drying and conveying system, garbage incineration system, combustion air system, waste heat boiler system, slag conveying system, flue gas purification system, steam turbine Generator system, automatic control system, public system, leachate treatment system, etc.

The project adopts the configuration of “three furnaces and two machines”: single furnace processing scale is 825 tons/day, processing scale: domestic waste 2250 tons/day + sludge 500 tons/day (water content not higher than 80%), incinerator type All are mechanical grate furnaces; the installed capacity is two 30MW condensing steam turbines. The waste heat boiler adopts a sub-high temperature and sub-high pressure (485℃, 6.4MPa) waste incineration boiler, which can maximize energy saving and consumption reduction. The flue gas purification system adopts the purification process of “SNCR + semi-dry method [lime slurry] + dry method [Ca(OH)2] + activated carbon adsorption + bag filter + SCR”.