How to adjust the sand particle size of the roller sand making machine?

The hydraulic system of the roller sand making machine can b…

Tel: 86-379-65160016

Fax: 86-379-65160018

Email: export@lylzzg.com

2021-12-28

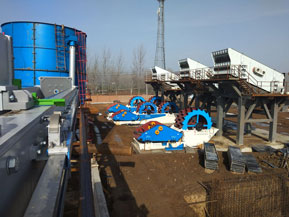

Tailings dewatering and dry stacking is a new technology of tailings disposal that has emerged in recent years, and is mainly a technical means developed for the treatment of tailings ponds. Longzhong Heavy Industry has developed a tailings dry discharge screen, which can also be called tailings dewatering screen. This equipment came out, mainly used to treat tailings ponds. The tailings dewatering screen is combined with a new process of tailings dry discharge. The specific operation process is: the tailings slurry output by the beneficiation process is concentrated in multiple stages, and then processed by dehydration equipment such as a dewatering vibrating screen to form a slag with low water content, easy precipitation and solidification, and storage on the site. The slag can be transported to a fixed location. Perform dry storage. After repeated tests by the manufacturer, the product performance meets the requirements.

After the tailings are dehydrated, they can reach a dry pile without entering the tailings pond, which can reduce the investment in the tailings pond. In addition, the tailings can be used comprehensively after dehydration, which is not conducive to improving the comprehensive utilization of resources, reducing land occupation, and protecting the environment. A permanent solution to eliminate hidden dangers in tailing pond protection.

There are many benefits to using this equipment for dewatering tailings.

1. After the tailings are processed, bricks can be made to produce aerated bricks and small solid bricks;

2. With the extension of the original slurry discharge to the tailings pond, the dry beach of the tailings pond is insufficient, does not meet the guarantee requirements and cannot find a suitable place or extends the service life of the tailings pond (the storage capacity can be increased by 1/ 4~1/3 above);

3. The closed tailings pond can be reused for dry discharge and stacking, which can increase the storage capacity by 20-30%;

4. The original slurry discharge tailings pond can be dammed with dry discharge to ensure reliability.

5. Use dry slagging, filling pits, and farming;

6. The location of the tailings pond in the mining area is seriously leaking water environment