20 tph sand washing and dewatering screen for sale

The widespread use of machine-made sand has made the sand ma…

Tel: 86-18736301510

Fax: 86-379-65160018

Email: export@lylzzg.com

2019-04-09

The coarse coal slime dewatering machine is a kind of solid-liquid separation equipment, which can continuously filter a large amount of sludge. The product is made of high-strength materials, featuring large processing capacity, high dehydration efficiency and long service life. The coarse coal sludge dewatering machine is widely used. In the solid-liquid separation of various industries, the bearing life of the configured bearing is long, and the high-quality filter belt is used to fully ensure the performance and quality of the filter press.

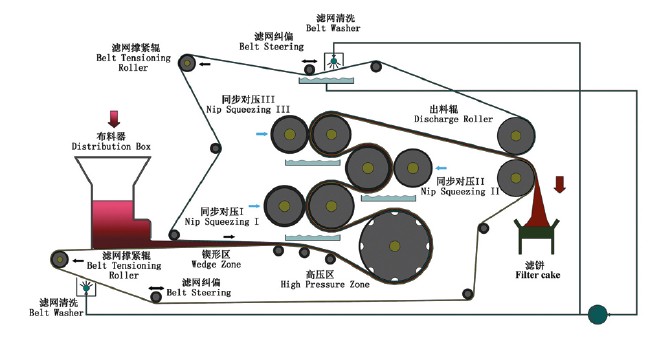

The slime belt filter press is divided into three steps for filtration and dewatering:

Gravity dewatering zone

The sludge of the wastewater treatment plant is pumped into the sludge agitation tank and mixed with the polymer agglutinating agent (polymer), so that the fine suspended particles in the sludge are bridged by the polymer agglutinating agent to form a latex (floc). The larger particles are then flowed by gravity from the upper end of the agitation tank to the subsequent press dewatering operation.

2. Pressure dewatering zone

After the sludge enters the pressure dewatering zone from the gravity dewatering zone, the upper and lower filter cloths begin to squeeze the sludge to dewater.

3. Pressurized dewatering zone

The sludge moves into the pressurized dewatering zone with the filter cloth. Between the six vertical rollers, the diameter of the roller is gradually larger and smaller, and the pressure is gradually increased from the smaller, and the upper and lower filter cloths are on different rollers. The shearing force generated on the sludge by changing the upper and lower positions causes the capillary-bound water in the gelatin mud to be squeezed out to produce a relatively dry sludge cake.

The scientific design and reasonable layout of the slime dewatering machine ensure that the filter press has high dewatering performance. The change of the contact angle of the filter belt ensures the best combination of pressure and shear force, thus greatly improving the solid content and dewatering efficiency of the mud cake.

The tension of the filter belt is realized by the inflated cylinder, so that the whole filter belt maintains a constant tension, and the tension change is not caused by the change of the feed amount, which is convenient for operation and management.

The filter press has a pneumatic control system that automatically detects the position of the filter belt on the pressure roller and automatically corrects the deviation. The wide-filter coarse coal sludge dewatering machine is also equipped with an automatic sludge feeding device to ensure that the sludge enters the filter belt in a balanced manner, thereby improving Filter efficiency and extend the life of the filter belt.

Slime dewatering machine is widely used in dry tailings, sand washing sludge dewatering, construction piling sludge, mud cleaning system, paper sludge, textile printing and dyeing sludge, leather sludge, mine beneficiation mud dewatering, food plant activated sludge, circuit board Sludge, ceramics, marble polishing sludge, electroplating sludge, washed kaolin sludge, dewatering of clean coal in coal washing plant, sediment silt in river pond, organic sludge in chemical plant, etc.