20 tph sand washing and dewatering screen for sale

The widespread use of machine-made sand has made the sand ma…

Tel: 86-18736301510

Fax: 86-379-65160018

Email: export@lylzzg.com

2021-07-06

The double-shaft circular vibration sieve is currently widely used in various coal mining enterprises, which can maximize the quality and efficiency of coal screening, reduce the efficiency of failures in the production process, and promote its safe and stable continuous operation. The working principle of the double-shaft circular vibration sieve.

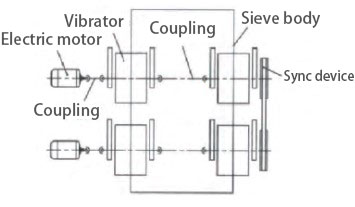

The working principle of the double-shaft circular vibrating screen is shown in the figure below. According to the figure, we can see that the working process of the double-shaft circular vibrating screen is mainly driven by two motors through the synchronization device to effectively promote the synchronous operation of two sets of eccentric vibrators, driving the vibrating screen on the spring support device according to the specified frequency Carry out circular trajectory movement to promote materials smaller than the screen hole size to pass through the screen plate.

The start-up operation of the vibrating screen must ensure that its operating frequency meets the requirements of the design drawings. There must be no additional devices on the screen frame, and no welding work can be carried out. Any fasteners on the double-shaft circular vibrating sieve must be kept in a fastened state. For the long-term use or long-term use of the double-shaft circular vibrating screen, the manager must arrange for professionals to add new grease to it. The management department assigns maintenance personnel to conduct a comprehensive inspection and maintenance of various equipment, scientifically judge and analyze whether the equipment has failure factors, and take effective preventive and solution measures in a timely manner.

Common problems of circular vibrating screen

(1) The intermediate coupling between the vibrator units has a deformation problem, and the phase angle difference between the two end flanges has caused the two vibrator units to be out of synchronization, which affects the amplitude of the screen frame. In response to this problem, the staff should take a solution to replace the new intermediate coupling in time, and the coupling must have passed the dynamic balance test.

(2) The vertical height of the vibrating screen is set too large, so when sieving coal materials, the material will have a huge impact on the vibrating screen, resulting in the occurrence of the vibrating screen: complex vibration phenomena are not conducive to the smooth operation of the vibrating screen . In response to this problem, the staff should scientifically optimize and adjust the feeding method, by adding a buffer plate or setting a wide slot feeder.

(3) Coal mining enterprises blindly pursue economic benefits in production, and thus choose to continuously expand production capacity and increase the throughput of double-shaft circular vibrating screens. In this working condition for a long time, the vibrating screen will be more easily damaged, which is not conducive to effectively extending its service life. Therefore, coal mining enterprises should scientifically use double-shaft circular vibrating screens to effectively expand the screen holes or increase the inclination of the vibrating screen by setting a layer of screen mesh.