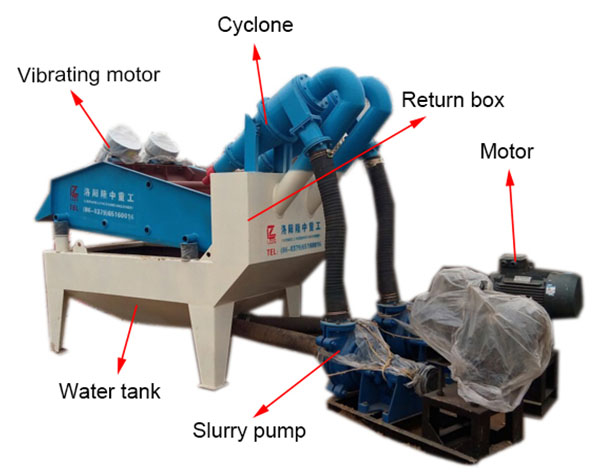

20 tph sand washing and dewatering screen for sale

The widespread use of machine-made sand has made the sand ma…

Tel: 86-18736301510

Fax: 86-379-65160018

Email: export@lylzzg.com

2021-06-04

The fine sand recovery machine is currently an important equipment in the fine sand production line. It can recover most of the fine sand, which has a great impact on the quality and grade of the sand. The following are several faults and corresponding problems that may be encountered during the use of the equipment Solution.

In the operation, if it is found that the amount of fine sand recovered is significantly reduced or there is a small amount of sand leakage, it is necessary to check whether the screen is broken or the bolts that fix the screen are loose. Then, in the face of this situation, its solution is to change the screen or tighten the bolts.

After the recovery machine has been working for a period of time, in the constant vibration, the bolts on the connecting frame are loosened or the bolts of the bearing seat are loosened. The troubleshooting method is to tighten the bolts and conduct careful inspection.

When you find that the transmission is very noisy, it is the change in the gear spacing caused by the gears. The general way to deal with this kind of problem is to add enough grease, and at the same time adjust and tighten the anchor bolts of the reducer.

In addition, the damage of the bearing and the fracture of the screen carriage will also produce noise, and the bearing or the screen carriage should be replaced at this time.

Generally there are sundries in the mud. Be careful not to let the oversized sundries enter the mud. It is best to connect the outlet of the dewatering screen directly to the inlet of the fine sand recovery machine, so as to prevent sundries from entering the high-pressure pump during work. .

The reasons for material deviation may be: 1) Two motors are running in the same direction; 2) One of the motors is damaged. At this time, the following measures can be taken: 1) Adjust any two-phase wiring of one motor to make the two motors run in reverse; 2) Replace the damaged motor.

The reasons may be: 1) The angles of the eccentric blocks at both ends of the vibration source are not the same; 2) The spring is uneven or damaged. Take corresponding measures: 1) Adjust the eccentric blocks at both ends of the vibration source at the same phase and angle; 2) Replace or select a spring.

Damage to the seal ring or oil cut can easily damage the bearing. The cause of this failure is that it has not been repaired and cleaned for a long time, so it is necessary to refuel in accordance with the regulations and replace the seal ring in time.