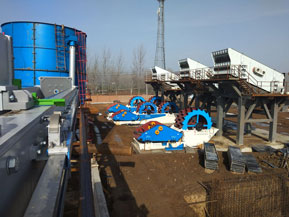

Iron tailings treatment to filling the goaf

In recent years, with the rapid development of backfill mini…

Tel: 86-18736301510

Fax: 86-379-65160018

Email: export@lylzzg.com

2021-08-17

The widespread use of machine-made sand has made the sand making industry shine. However, with the increasing demand for sand and gravel aggregates. Recently, some users have consulted on the price and Parameters. Let me introduce you in detail below.

Since there are many manufacturers producing sand washing and dewatering screens, the production process and equipment quality of each manufacturer are different. The 20 tons/hour sand washing and dewatering screen designed and manufactured by LZZG is a small sand washing and dewatering screen. The machine occupies a small area and has a high output. The sand washing tailings dewatering screen can be used in chemical industries such as dry tailings, concentrate dewatering, smelting slurry concentration, coal slime dewatering, and carbon slurry separation. It has a large processing capacity and a significant screening effect. The dehydration effect is particularly good and other features are deeply loved by users.

Our sand washing dewatering sieve with an output of 5 tons per hour in the sand washing field has not only 100 meshes, but also 30 meshes, 40 meshes, 50 meshes, 80 meshes, 100 meshes, 150 meshes, 200 meshes, etc. according to the user For users who do not have a specific mesh, the screens we configure are about 100 meshes. Users can contact us according to their needs.

The small sand washing and dewatering screen has the advantage of low price. Every user who orders a machine in our factory, one is also at the factory price, and our sand washing and dewatering screen has a low failure rate. The use of wear-resistant polyurethane screens reduces customers Maintenance costs. If you have any needs in this regard, you can consult us.